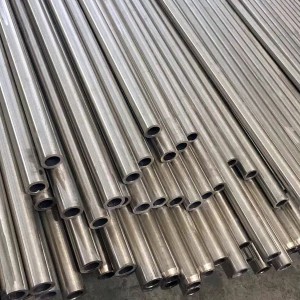

Nickel Alloy 20 (UNS N08020) /DIN2.4660

| ʻO ke kinikini | mea | C | Si | Mn | S | P | Ni | Cr | Nb+Ti | Fe | Cu | Mo |

| ʻO ke kinikini 20 | Min |

|

|

|

|

| 32.0 | 19.0 | 8*C |

| 3.0 | 2.0 |

| Max | 0.07 | 1.0 | 2.0 | 0.035 | 0.045 | 38.0 | 21.0 | 1.0 | kaulike | 4.0 | 3.0 |

| Kūlana ʻo Aolly | Ikaika tensile Rm Mpa Min. | Ikaika hāʻawi RP 0.2 Mpa Min | Hoʻolōʻihi He 5 % iki |

| Hoʻopili ʻia | 620 | 300 | 40 |

| Ka nui o ka paʻag/cm3 |

| 8.08 |

Koʻokoʻo, Pā, Uea a me ka Waihona Hana- ASTM B 462 ASTM B 472, ASTM B 473, ASME SB 472, ASME SB 473,

Pā, Pepa a me ka ʻĀpana- ASTM A 240, ASTM A 480, ASTM B 463, ASTM B 906, ASME SA 240,

Paipu a me ka Tube- ASTM B 729, ASTM B 829, ASTM B 468, ASTM B 751, ASTM B 464, ASTM B 775, ASTM B 474,

ʻĒ aʻe- ASTM B 366, ASTM B 462, ASTM B 471, ASTM B 475, ASME SB 366, ASME SB-462, ASME SB

ʻO ke kūpaʻa maikaʻi loa i ka ʻōpala i ka waikawa sulfuric

ʻO ke kūpaʻa maikaʻi loa i ka haki ʻana o ka chloride stress corrosion

Nā waiwai mechanical maikaʻi loa a me ka hiki ke hana ʻia

Ka hoʻoheheʻe ʻana o ka carbide liʻiliʻi i ka wā o ka hoʻopili ʻana

ʻOi aku ka maikaʻi ma ke kū'ē ʻana i ka pala i nā waikawa sulfuric wela