Nikala 200/Nikala201/ UNS N02200

| ʻO ke kinikini | mea | Si | Mn | S | Ni | Fe | Cu |

| Nikala 200 | Min | ||||||

| Max | 0.35 | 0.35 | 0.01 | 99.0 | 0.4 | 0.25 | |

| Manaʻo | ʻO 0.02 ka element Nickel 201 C, ua like nā element ʻē aʻe me Nickel 200 | ||||||

| Kūlana ʻo Aolly | Ikaika tensile Rm Min Mpa | Ikaika hāʻawi RP 0. 2 Min Mpa | Hoʻolōʻihi He 5 Min % |

| hoʻomehana ʻia | 380 | 105 | 40 |

| Ka nui o ka paʻag/cm3 | Kiko Heheʻe℃ |

| 8.89 | 1435~1446 |

Koʻokoʻo, Pā, Uea a me ka Waihona Hana- ASTM B 160/ ASME SB 160

Pā, Pepa a me ka ʻĀpana -ASTM B 162/ ASME SB 162,

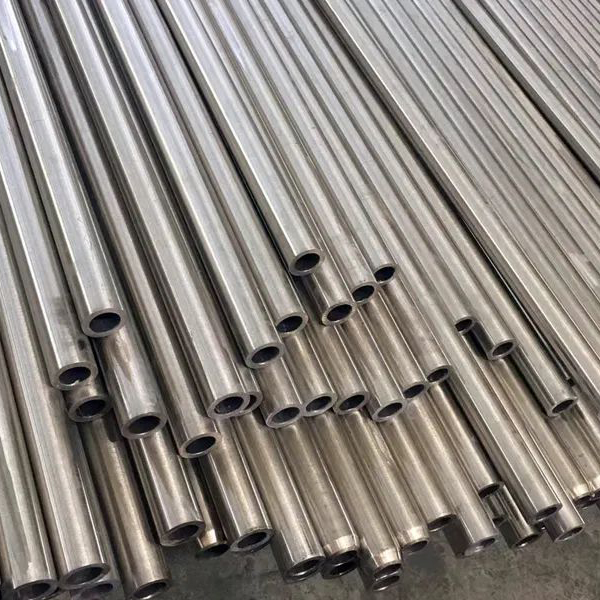

Paipu a me ka Tube- ASTM B 161/ ASME SB161, B 163/ SB 163, B 725/ SB 725, B730/ SB 730, B 751/ SB 751, B775/SB 775, B 829/ SB 829

Nā mea hoʻohui- ASTM B 366/ ASME SB 366

● Kūpaʻa loa i nā kemika hoʻemi like ʻole

● Kū'ē maikaʻi loa i nā alkalis caustic

● Hoʻokele uila kiʻekiʻe

● Kūpaʻa maikaʻi loa i ka wai i hoʻoheheʻe ʻia a me nā wai kūlohelohe

● Ke kū'ē i nā hopena paʻakai kūlike a me ka alkaline

● Kū'ē maikaʻi loa i ka fluorine maloʻo

● Hoʻohana nui ʻia e lawelawe i ka soda caustic

● Nā waiwai wela, uila a me ka magnetostrictive maikaʻi

● Hāʻawi i kekahi kū'ē i nā waikawa hydrochloric a me sulfuric i nā mahana a me nā ʻano haʻahaʻa